Wagner FarmFive-pile system to efficiently compost farm’s 50-50 manure-straw waste

In suburban Glenview, Illinois, Wagner is an 18-acre functional farm with livestock and crops. But the property is exceptional since it is owned and operated by the Glenview Park District and also includes a heritage center and farm-themed play equipment for children.

Like any farm, Wagner produces tons of waste. But efficiently composting that waste is doubly important because of the farm’s dual role as an educational destination and its proximity to residential neighborhoods.

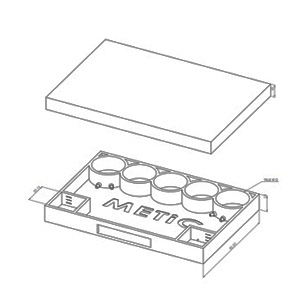

The student group of Alex Choi, Jason Lee, Jessica Kang, Kareena Sharma, and Lauren Simitz proposed a five-pile system to compost Wagner’s 50-50 manure-straw waste more efficiently. This method, aerated static pile composting (ASP), eliminates the need for laborious turning or mixing the pile to aerate.

This is very helpful for a farm that doesn’t have very much manpower. This solution can streamline the composting process and make it much easier and neater so it’s less of an eyesore to visitors.

Problem

Efficiently composting the farm’s tons of waste is doubly importing because of the role as an educational destination and proximity to residential neighborhoods.

Solution

Aerated static pile composting (ASP), eliminating the need for laborious turning or mixing the pile.

Development Process

The students’ work began with background research, learning about composting chemistry and the factors that lead to healthy composition. They looked at the existing composting system at Wagner, the positives and negatives of other composting methods, and various aeration systems.

They decided ASP is the method that best satisfies Wagner Farm’s needs because the method is space efficient, requires little maintenance, and aerates effectively. These factors lead to healthy and quickly produced compost.

How it Works

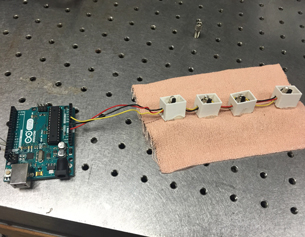

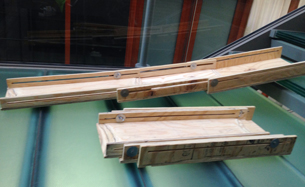

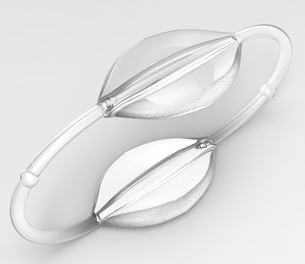

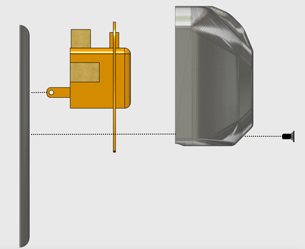

The ASP uses a piping system connected to an air pump to push air through the compost pile from the perforated pipes inside. A layer of finished compost on top of the manure and straw acts as a carbon filter for the odor. A layer of wood chips sits between the pipes and manure to prevent particulate from entering the system and to better disperse the air.

The compost is split up into five batches, with each pile cycling compost every 10 weeks as it matures. This separation results in more even composting. Finally, a slight grade and pipe caps enable drainage and cleaning, if necessary.

Current Status

The students planned to build the system at the farm. But because of mandated social distancing, they provided a plan the farm owners would assemble instead.

Updated August 2020

CourseDesign 384: Interdisciplinary Design

Group MembersAlex Choi, Jason Lee, Jessica Kang, Kareena Sharma, Lauren Simitz